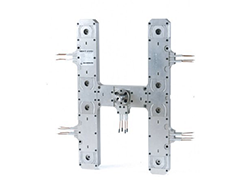

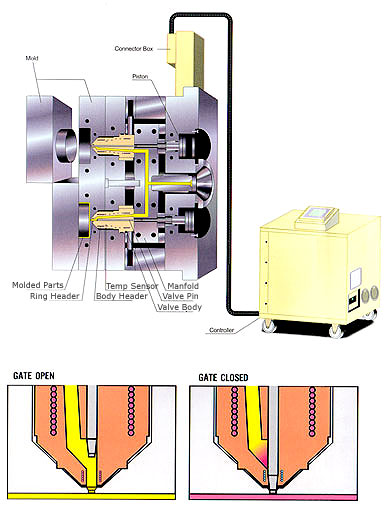

Mechanical Valve Gate System incorporates a valve pin activated by pneumatic drive. We have full-line of valve gate including options, with the length up to 400mm, gate size of 0.8 - 8.0mm. Various kinds of valve gate in accuracy and function are available. Depends on application, valve gate with tip heater is available, too.

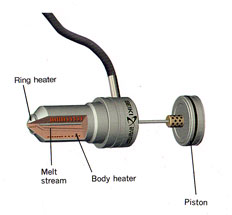

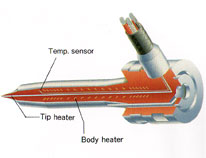

The spear has a double heater structure consisting of a tip heater and a body heater. The spear tip has been modified to directly heat itself. There are a large variety of spears available to accommodate different resin types and applications.

It features user-friendly hot runner operation and a high degree of accuracy. S2000 controller can be monitored/controlled through a Windows PC by adapting optional elements such as signal tower, switch box, big-screen entry unit, PC connection module. Moreover, it is possible to centrally control more than one controller through one PC. it is also possible to put temperature and output current on record (CSV format) by means of its logging function.

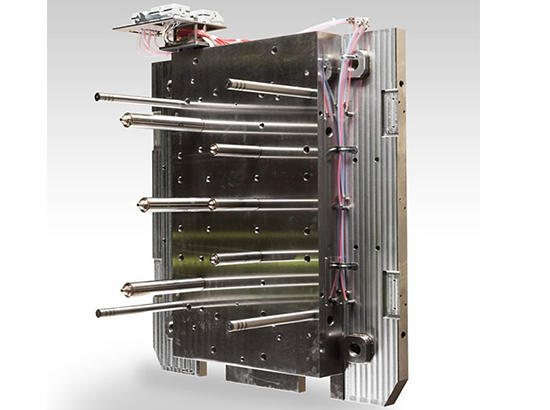

This Hot half package includes all hot runner parts (clamping plate, spacer block, back plate, connector box), excluding cavity plate. We design, produce, assemble, pre-wire a Hot half to fill the customer's order.

We help customers in terms of lightening their work load with a speedy delivery. And we control all the relevant drawings collectively in an effort to provide our customer with overall future service works including maintenances.

General Construction

The system consists of probes and a manifold that are assembled inside the mold. A controller maintains the temperature of these probes and manifold.

Seiki Spear Probe

The patented Spear System is a two stage probe consisting of a body heating element and a separate tip heating element. Various types of spear probes are available for a wide variety of molding applications.

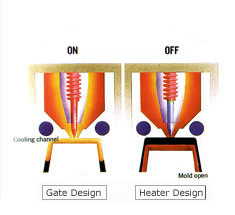

The Principle of the TIP HEATER

An internal body heater maintains the melt temperature of resin around the probe. A separate tip heater turns “ON” to melt the gate open. Cooling holes near the gate areas always keep both the cavity and gate areas evenly cooled. When the tip heater turns “OFF”, the gate area is cooled down by heat transfer, and the resin in the gate area is rapidly solidified, sealing the gate.